Quartersawn Process

What Is Quatersawn?

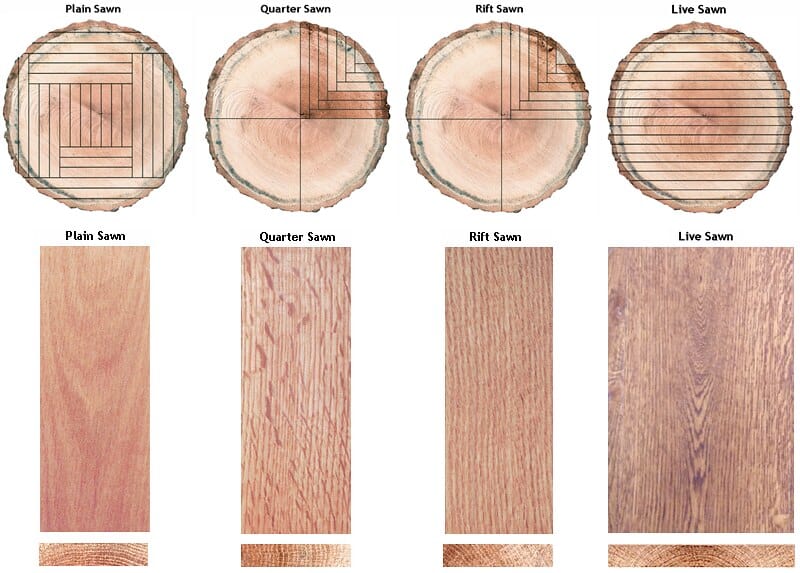

Lumber is quartersawn for two main reasons. The first and probably most important to all woodworkers is the stability of the lumber that they are working with. By looking at the properties of each species of lumber, notice the amount of tangential and radial shrinkage each has. These numbers tell you how much that species moves in thickness and width with changes in moisture content as the wood dries. A long time ago, woodworkers discovered that green cut lumber that was processed from logs where the annual rings of the log ran perpendicular to the face of the lumber-produced material that did not expand and contract as much with changes in moisture content. This lumber was produced first by cutting the log into half, and then the halves into quarters. After being cut into quarters, each quarter section is placed on the mill in a position so that the annual rings are as close to 90 degrees (perpendicular) to the face of each board as possible when sawn from each quarter section. The sawn lumber has tight, straight, parallel grain lines running the length of the board. The resulting lumber’s properties are to shrink more in the thickness of the piece and less in the width of the piece. The end result is lumber that moves less across the width of the piece and is more stable. In a plain-sawn piece of lumber, the opposite is true due to the parallel orientation of the annual rings to the face of the piece. (Please refer to the Quarter-sawing diagram)

The second reason for quarter-sawing lumber is the resulting appearance of the lumber produced. In all species, the grain of the lumber is tight, straight, and parallel. This is different than that of lumber that is plain-sawn. In certain species such as Oak and Sycamore, the face of the quartersawn lumber will display a prominent ray fleck on the face of the lumber. These rays are part of the cell structure of the growing tree that radiate outward from the pith of the log to the sapwood. When the log is sawn with the annual rings perpendicular these rays are bisected and show up on the face of each piece of quartersawn lumber as a shiny band. These bands vary in width from species to species and also from tree to tree. When sawn, each log reveals its own unique figured pattern of ray flecks on each sawn piece of lumber. This is only visible in those species that have these rays in the cellular structure.

Lumber that exhibits these ray flecks, or in species that do not have rays in the cellular structure where the annual rings are between 60 to 90 degrees to the face of the lumber are called quartersawn. Both quarter-sawing and plane-sawing, depending upon the orientation of the annual rings to the face of each piece of lumber, will yield some rift sawn lumber. Riftsawn lumber has a straighter grain pattern much like the quartersawn, but will not exhibit the ray flecks in those species that have rays. The annual rings of the lumber will be at an angle between 30 and 60 degrees to the face of the piece.

Most production mills do not quartersaw due to the increased time that it takes to quarter the log and the decreased lumber volume that will be produced from each log. To produce high-quality quartersawn lumber the mill first needs to start with a large log that when quartered will produce lumber of good width. This usually starts with a log that is at least 20″ and larger in diameter on the small end and straight. Another consideration is the tightness of the growth rings of the log. A slow-growing tree with many rings to the inch will yield lumber that is much easier to machine and work than that of a fast-growing tree with a small number of growth rings to the inch. Quartersawn lumber also takes greater care in drying due to the fact that the cells in this orientation give up their moisture slower than lumber that is plainsawn. All of these factors combine together to raise the cost of the end product.

Those woodworkers that have used good quality quartersawn lumber would tell you that it is definitely worth the additional cost. There is a greater volume of 4/4 quarter sawn lumber available than that of 5/4 and thicker. In the Oaks, the quartersawn thick stock can be a kiln operator’s nightmare to dry without drying defects. That is why much less thicker stock is available, and when it is it commands a premium price. There are a select few producers that will “walk the kiln drying tight hope” to dry thick quartersawn stock or tie up the inventory on the air dry yard for a long time.

For those that manufacture Mission Style furniture, quartersawn White Oak is the species of choice. This style of furniture making was popularized by the designs of Gustav Stickley. Today quartersawn lumber has seen somewhat of a rebirth in its use. It is still used in furniture but has also been used in flooring applications for the stability of lumber. It is a good choice to use quartersawn lumber for flooring in an application where the flooring is installed over radiant heating. The quartersawn lumber will react less to the changes in temperature and humidity of the room when installed over the radiant heat system. Quartersawn lumber is also specked out for architectural millwork applications for its stability and appearance. It is also used for high-end cabinetry and musical instruments. Lumber is quartersawn for two main reasons. The first and probably most important to all woodworkers is the stability of the lumber that they are working with. By looking at the properties of each species of lumber, notice the amount of tangential and radial shrinkage each has. These numbers tell you how much that species moves in thickness and width with changes in moisture content as the wood dries.